Wechat

Wechat

Mobile

Mobile

Wechat

Wechat

Mobile

Mobile

+ Absorbents are widely used in FGD devices, including limestone, lime, brucite, carbide slag, waste soda solution, etc.

+ Fuel can be used in a wide range of applications, such as coal-fired, heavy oil, ori oil, petroleum coke and other fuel boilers tail gas treatment;

+ The flue gas with sulfur content up to 8% of the fuel can be treated with a strong adaptability to the range of sulfur content in the fuel.

+ It is especially suitable for deep desulfurization projects such as high sulfur coal and low so and emission concentration in key areas.

+ The unit has strong adaptability to load variation, and can meet the stable operation of the unit in the range of 30-100% load variation.

+ The desulfurization efficiency is higher than 95% and the highest is 99.5%.

+ Special tray technology, effective reduction of liquid/gas ratio, conducive to uniform distribution of flue gas flow in the tower, saving energy consumption, convenient maintenance of absorber internals, obvious advantages of energy saving;

+ The utilization ratio of absorbent is high, and the ratio of calcium to sulfur is low to 0.2 ~0.03.

+ The by-product has high purity and can produce more than 95% commercial grade gypsum.

+ The dust removal efficiency of flue gas from coal-fired boilers is high, reaching 80%.

+ A variety of technical methods can meet the upgrading technical transformation of desulfurization unit, such as cross spray layer, double trays, high efficiency energy-saving oxidation system, high efficiency spray washing technology, gradient zoning composite tower technology, etc., and can achieve the maximum reduction of the amount of retrofit projects to meet the requirements of the project schedule.

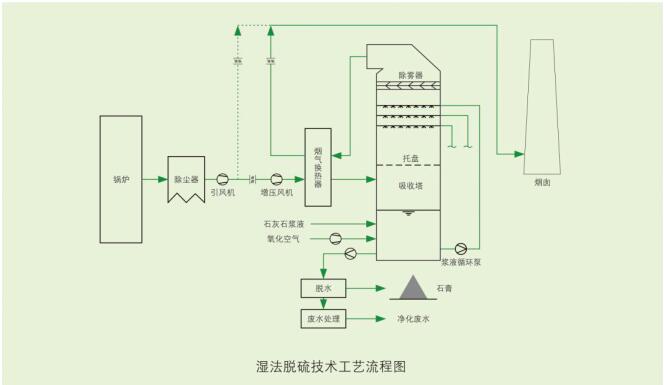

System Composition

+ Limestone Storage and Transportation System + Gypsum Dehydration System

+ Preparation and Supply System of Limestone Slurry and Storage and Transportation System of Gypsum

+ flue gas system + SO2 absorption system

+ slurry discharge system + process water system

+ Compressed air system

Recommended Scope of Application

+ 100MW and above large and medium-sized newly built or retrofitted units;

+ Sulfur content in coal combustion ranges from 0.5% to 5%.

+ The required desulfurization efficiency is above 95%.

+ Areas with rich limestone and extensive comprehensive utilization of gypsum

Flow Chart of Wet FGD Technology