Wechat

Wechat

Mobile

Mobile

Wechat

Wechat

Mobile

Mobile

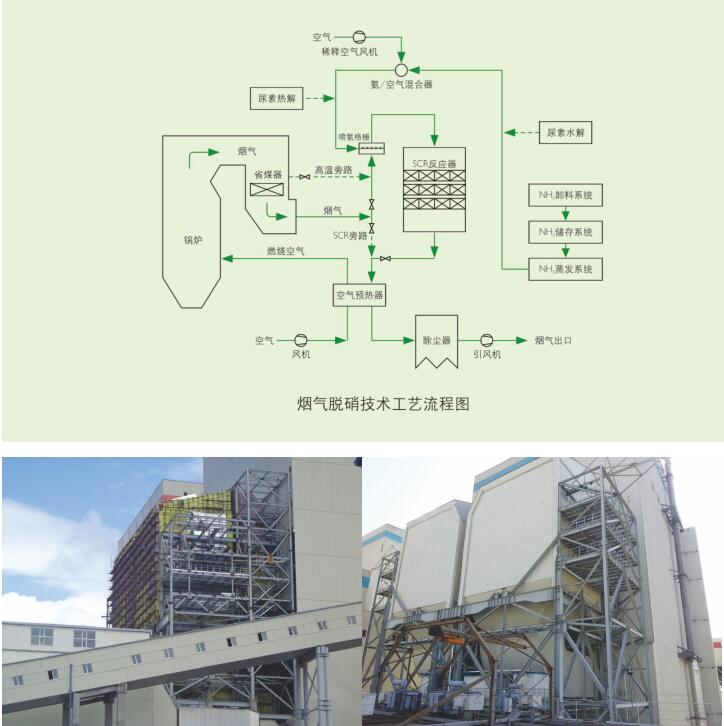

Selective Catalyst Reduction Flue Gas Denitrification (SCR) technology uses a vertical catalyst reactor to react with reductants such as liquid ammonia, ammonia water or urea to remove nitrogen oxides (NO x) in flue gas. Ammonia prepared from reductant is diluted and mixed with flue gas from boiler. Under the action of catalyst, NOx is reduced to harmless nitrogen (N2) and water (H2O). Combined with CFD digital simulation and physical model verification, it ensures the uniform distribution of flue gas field in all sections of the denitrification reactor, ensures the uniform mixing of reducing agent, and adopts different ammonia spraying measures to meet the requirement of denitrification efficiency of 95%, NH3 escape less than 3 ppm, and equipment use efficiency is high. SCR technology is currently the world's most advanced power plant flue gas denitration technology, with a market share of 98% in the global flue gas denitration field.

Process Flow

SCR reactor is usually located downstream of flue gas from solid slag or liquid slag removal boilers in coal-fired and oil-fired power plants, between economizer and air preheater. At this time, flue gas temperature is 300-4000C, which is the optimum temperature range for denitrification reaction. In general, ammonia is used as a reactant. Before entering the denitrification reactor, the flue gas is first introduced into the mixture of NH3 and air (5% ammonia). Ammonia is evenly distributed on the cross section of the flue gas passage by many precise nozzles. The flue gas flows from top to bottom, the surface of the catalyst maintains a certain temperature, and NOr is on the surface of the catalyst and on the cross section of the flue gas passage. The reaction of ammonia produces N2 and H20. N2 and H20, which are components of air, do not pollute the atmosphere. The flue gas treated by denitrification equipment passes through the air preheater at the tail of the boiler and enters the ESP or desulfurization system arranged downstream of the flue gas.

Characteristic

+ After the SCR device is arranged in the boiler economizer, it has little effect on the performance and structure of the boiler.

+ Denitrification removal rate is high, up to 90%.

+ The performance of desulfurization unit is reliable and stable, and the equipment availability rate is 98%.

+ Catalytic reduction has a long life and can last up to 24,000 hours.

+ NH3 escape rate < 3ppm

System Composition

+ anhydrous ammonia storage system

+ Ammonia/Air Mixing System

+ Denitrification Reactor System

+ Catalyst system

+ Flue gas system

+ Soot blowing system