Wechat

Wechat

Mobile

Mobile

Wechat

Wechat

Mobile

Mobile

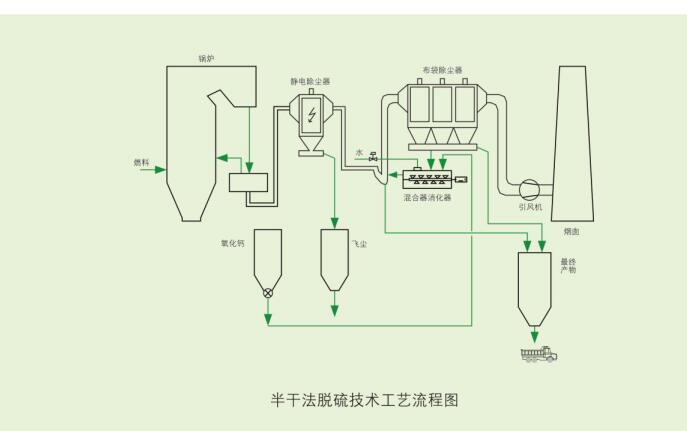

NID (Novel Integrated Desuphurization) is a new generation of desulfurization and dust removal technology. It uses quicklime [CaO] or hydrated lime [Ca (OH)] to absorb SO and other acidic gases in flue gas after humidifying with water. It is especially suitable for the treatment of flue gas desulfurization and dust removal of small and medium-sized thermal power units below 200MW.

Characteristics

+ The structure is compact. There is no separate lime digestion device, but digestion and mixing integrated operation, occupying very little space. The reactor also occupies a small volume.

+ The operation is simple and reliable. A rectangular reactor at the front of the dust collector was replaced by an integrated desulfurization tower. The integrated design of digestion and mixing avoids excessive mechanical pressure on the equipment due to the flow direction.

+ The load can be adjusted.

+ Economic and efficient. SO and hydride (HCI, HF, etc.) are absorbed almost completely at the same time. The digester allows power plants to use quicklime instead of commercial slaked lime, while producing high-quality slaked lime to better clean the flue gas.

System Composition

+ Reactor

+ Mixer

+ Digestor + High Concentration Electric and Bag Dust Collector after Desulfurization

Recommended Scope of Application

+ Especially suitable for desulphurization and dust removal in thermal power plants, sintering machines and glass furnaces of iron and steel enterprises with a scale of 300 MW or less in water-deficient areas.